TR4A

(1965-1967)

First things first – should that hyphen be there or not? (TR-4A vs. TR4A)

I originally put the hyphen in the title because that’s the way the name appeared in Triumph’s first ad for the car : “This month Triumph introduces next month’s two best-selling sports cars.” However, it doesn’t appear that way in many other places: not in the owner’s or workshop manuals (though the workshop manual talks about the “TR.4A” a fair bit), nor in Robson’s nor Piggot’s books. The Kastner Competition Preparation Manual supplement talks about the TR-4A, though.

I guess the answer is that they’re all correct!

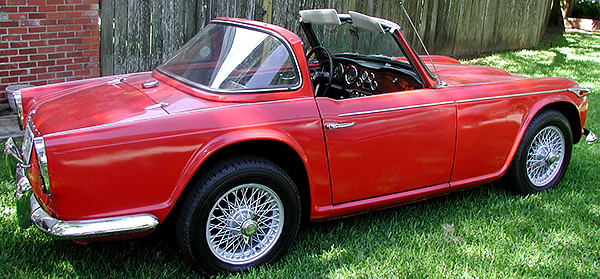

Externally, the TR4A looks like a continuation of the TR4. The cars share a few pieces of sheet metal and have much the same engine, but most everything else differs. For starters, the TR4A is on a much wider frame and a redesigned suspension. The front suspension is adjustable for camber and the rear suspension is independent – or could be. Triumph dealers in the US convinced Standard-Triumph that they could continue to sell non-IRS cars at a good price, and Triumph responded with a clever solid axle design that fit into the IRS frame.

A History of the TR4A

The TR4A – beginning of a major transition

Apparently there was always the feeling at the factory that the TR4 was an interim model. Financial woes caused the company to introduce the TR4 when it did; otherwise a car to replace the TR3A mith have been even more complex, technically more advanced and in general more exciting. It might have been the TR4A!

The origins of Harry Webster’s IRS design stem from around 1962, and the basis for the TR4A stems from that as well; it was expected that the change to IRS would cause a radical change in the behaviour of the car, so it would be necessary to begin a new project and plan a new model. If evolved steadily until the completed project was vastly different from the car it was to replace. According to Robson, “the TR4A was as different, in its own way, from the TR4, as that car had been from the TR3A. It was yet another step along the transitory path which was to convert the rugged little TR2 into the smooth and thoroughly modern TR6.

Webster’s team was faced with a major problem – although they had been asked to design an independently-sprung TR, they also had to make provision for the United States, where the cars would still be sold with a solid axle. No matter how much Leyland tried, the North American distributors would not give up the idea that they could still sell TRs with a live axle at the right price, that roadholding at the limit was not yet critical to sales there, and that irs was bound to be more expensive. So it was agreed that the new chassis would be amenable to both layouts, and that both layouts would be available in the US. It was not ever considered reasonable to keep the narrow TR4 chassis for the live axle cars.

The new chassis-frame had a radically different layout from the previous cars. The rear suspension was semi-trailing wishbone plus coil spring, that design having been proven on the Triumph 2000 saloon. Parts were not interchangeable between the two models, but they were philosophically the same. The TR4A kept lever arm shocks for ease of installation. The IRS cars received a massive pressed-steel bridge piece to support the differential casing and provide upper anchor points for the coil springs; the live axle cars didn’t have the bridge piece and got long half-elliptic leaf springs. When prototypes were made ready for the road, managing director Stanley Markland pronounced the new chassis “safe for 120 mph”!

Which, of course, brings us to the motivating unit. Markland wanted more power for the next model, but Triumph’s six cylinder engines really weren’t ready yet. So the decision was made to continue on with the tried-and-true 2138cc Vanguard derivative – aging design, wet liners and all. There was talk of punching this out from 87mm to 93mm bore to give a 2499cc dry liner engine, to provide an adequate jump in power from the TR4 to TR4A, but the prototypes didn’t give the hoped-for results. So the 2138cc engine was given its final boost, to 104bhp at 4700 rpm.

The TR4A was phased in smoothly at the beginning of 1965. Body production changes were limited to a new grille, decoration and badging, along with new body-to-chassis mountings. The press was happy to see an all-independent car, and Triumph was pleased to be the first British car manufacturer to have all-independent suspensions under every car in their line.

Unfortunately, the TR4A was not as fast on the road as the critics expected. (Neither was the TR4.) It wasn’t much faster than the TR3A with its optional 2.2 liter engine had been in 1959 – the TR4A had put on weight with age. Even by comparison with the TR2s of 1953 there had not been a dramatic improvement. Fuel consumption was worse. Product planners at Triumph were asked to make a quantum leap in performance and economy, not to mention extended high speed running (for the new European highways). This, combined with the new emission control laws in the US, spelled the end of the four-cylinder TR. For the 1968 model year, the TR250/TR5 answered the call with the old styling but a new engine.

A competition hiatus

The Factory had pretty much stopped competition by the time the TR4A came out – the last major TR-based competition cars were the powder blue Shell 4000 Rally Team TR4s of 1964. The Triumph 2000 had taken over competition in the rough-road European rallyes.

In the United States, however, ‘Kas’ Kastner continued his wizardry, using his ‘unfair advantage’ to wring 150 bhp and more out of the 2138cc powerplant. The SCCA went to great efforts to try to keep all entrants competitive, adjusting classes year-by-year to keep the racing exciting. Between Kastner’s engine work and Bob Tullius’s driving for Group 44, the TR4A dominated SCCA D-Production racing. But the TR4As have very little other competition history.

Member Pages

Pierre Col | (Lyon, France)

Chris Kantarjiev | (Palo Alto, CA)

If you would like your page added to this listing, please contact the webmaster.

TR4A Commission Numbers, Change Points, and Overall Production Numbers

(from Piggot’s Original Triumph TR):

- CTC 50001 – first TR4A, built January 1, 1965.

- CTC 50125 – Gearbox and clutch housing modified slightly.

- CTC 59836 – Packing pieces changed on front springs (presumably this is the change from short springs with aluminum spacers to slightly longer springs with no spacers).

- CTC 62191 – Stromberg carburettors deleted and twin SU HS6 substituted, still on same intake manifold, TW needles.

- CTC 62637 – Temperature sender and gauge modified.

- CTC 78684 – last TR4A, built July 10, 1967.

Suffix letters in Commission numbers

L (as 1st suffix letter) — left hand steer

O — overdrive

Total production numbers:

1965 13735 (CTC 50001)

1966 11097 (CTC 64148)

1967 3633 (CTC 75172)

There are clearly some omissions here – I know that CTC 7xxxxx has Stromberg carburetters, for example. Piggot’s numbers and change points are completely oriented towards the home (UK) market, and he neglects a number of details that pertain to export cars.

Buyer’s Guide, Spotter’s Guide and Parts Info

In addition to the items listed in the general Triumph Buyers Guide , there are a number of specific items of interest on the TR4A.

Assessing a TR4A for possible purchase is very much like assessing any Triumph. Due to the many mechanical similarities, most of the same strengths and weaknesses of TR4 or TR6 apply to the TR4A range.

- Engine: The engines generally took a lot of punishment, but ultimately that punishment shows in wear of cylinder bores, crankshafts, main and big-end bearings, thrust washers, etc. Liners and pistons are available in various sizes and are fairly straightforward to replace. Low oil pressure may be “cured” by replacing the oil pump and big end bearings (easily done with the engine in the car). Look for a missing radiator shroud as the source of overheating problems.

- Transmission: The later TR transmission is fairly bulletproof. Look for malfunctioning or maladjusted overdrive; the adjustment is simple, and swapping an OD into a non-OD is straightforward (if you can find the parts). The TR box is one of the nicest feeling gearboxes this side of a Hewland racing transaxle.

- Brakes: The electrical and hydraulic systems of these cars will show no surprises for those familiar with other Triumphs or indeed any other British-made cars. Weak brakes often mean poorly adjusted rear drums.

- Chassis/Frame: One of the most critical parts of any car is, of course, the chassis; the TR4A is no exception. The fore/aft strength of the car counts on solid sills. Clunks from the rear under power may indicate worn, missing or broken differential mounts; usually the front right mount wears and then breaks, followed quickly by its left rear counterpart. Loose or worn universal joints are another common source of noise at the rear; lubrication of these items is essential (and sometimes difficult). A nice addition to find is the rubber gaiters from a TR250 to cover the inner joints.

- Body: Apart from the sills, these cars have several other common rust points: the trailing end of the front fenders, where mud and muck gets caught behind the “access panels” (which seem to be rarely used), and the upper arches of the rear fenders. Rustproofing (and paint!) seems to have been applied to these areas after assembly, leaving much exposed metal.

This is an attempt to help differentiate the TR4A from the TR4 at a glance. It concentrates on US models; according to the photos in Bill Piggott’s Original Triumph TR , the UK model differ in some small details (notably front turn signals).

- Exterior: The most notable differences are the grille, which is an aluminum extrusion instead of a stamping, and the turn signal repeaters and parking lights, mounted on the fenders with chrome trim strips along the beltline of the car. The main turn signals are much larger (always white lenses). Bumper overriders have moved outboard, between main headlamps and turn signals. Bonnet is badged with smooth “TRIUMPH” lettering and the old Triumph Globe insignia. The bonnet bulge continues the later TR4 pattern, going the full length back to the opening edge. Lucas “tripod” lamps are not correct, even though they look quite lovely.The TR4A continues the use of 4-1/2J (15×4.5 inch) pressed steel road wheels, chromed nave plate and globe medallions. Piggott (and others) claims that these wheels are always painted silver, but I have evidence that some wheels in the US were painted Spa White . 60-spoke wire wheels (painted aluminum or silver, or dull or bright chrome) were offered as an option, with a chromed two-eared knock-off nut. “Silverstone” 15×5 alloy wheels were a competition option, both in magnesium and aluminum alloys.The TR4A was introduced with crossply tires (5.50/5.90.15) as standard, but it seems that most cars were deliverd on radials, usually Michelin X, in 165-15 size.

- It seems that the factory didn’t fit external mirrors. Most US Triumph dealers attached one or two “bullet” mirrors to the doors.

From the windscreen back, the TR4A looks essentially identical to the TR4. The top doesn’t disappear under the interior trim any more. The Surrey top is a desirable option; as far as I know, the factory never offered a hardtop, though there were aftermarket units available.

The taillight lenses are still all red, and the boot lid on IRS cars has an extra “IRS” badge. The exhaust was either twin silencers or a single large silencer mounted transversely with dual exhaust pipes. Reversing lights were a rare option, consisting of a pair of chromed housings mounted at either end of the bumper by the outboard bumper mounting bolts.

- Interior: dashboard in walnut veneer laminated on plywood; gauges have flat lenses with chrome trim and partially shrouded needles. Tachometer is on the left. Handbrake is mounted centrally on the transmission tunnel. The TR4A got two-speed windshield wipers, operated by a pull-out switch. Unlike the TR4, the TR4A has trimmed door tops – a glued-on panel that matches the interior trim color. Only one style of seat was offered throughout the TR4A’s lifetime, with plastic piping and straight seams on the inserts.

- Engine: carburetters varied over the lifetime between SU HS6 and Stromberg CD 175. The flame trap air cleaner arrangment seen on the TR4 is gone; most sources seem to agree that oval air cleaners are proper. There’s a large PCV valve that is plumbed between the chromed rocker cover and the intake manifold. The oil filler cap is not vented. Exhaust manifold is cast iron with two exit pipes (about the same configuration as the competition mild-steel header, but heavier). The radiator is wide with an integral header tank and a plastic overflow/recovery tank mounted on the manifold-side fender. There is no hole for a starter crank, even though the grille retains such a hole.

Numbering of Major Components

- Engine: engine numbers for the TR4 and TR4A have a ‘CT’ prefix and an ‘E’ suffix. Factory rebuilt engines have an ‘FRE’ suffix. Engines prefixed ‘CTA’ indicate that they have 83mm liners (1991 cc). This was not a factory option for the TR4A.

- Commission Number: Marked on a plate rivetted to the bulkhead on the spark plug side, the TR4A is prefixed ‘CTC’, with the lowest number being CTC50001. Rigid rear US cars still had the prefix ‘CT’ but were numbered in sequence with the ‘CTC’ cars. Some cars were exported from Coventry as kits for local assembly: an ‘ICTC’ prefix indicates that the car was built in Belgium. A suffix of ‘L’ indicates left-hand drive, and a suffix of ‘O’ indicates the overdrive option.This plate should also indicate the original paint color and interior trim style (leather or Vinyde) and color.

- Body: Body number is recorded on a stamped aluminum plate on the opposite bulkhead, and has the suffix ‘CT’.

After 25-35 years, it would not be a surprise to come across a TR4A with major components whose numbers do not match the listings above. Gearbox and differential swaps are common; we have even seen one car with TR4A body panels mounted on a TR4 frame. Much of the above information was taken from Bill Piggott’s Original Triumph TR .

Availability of spares

Due to the continuing, even increasing, popularity of the wide chassis Triumphs (TR4A/250/5/6), availability of spares is quite good. In fact, the TR4A didn’t have as many oddball items (green or green-striped hoses come to mind) so in some sense they have the best availability. Some body panels are hard to find, but the TR250 or TR6 part will often do.

Sometimes the original part as numbered in the TR4A parts manual is no longer available, but it will have been improved upon and superceded by a TR6 part. The lower inner front A-arm mounting bracket comes to mind; the TR6 part has two mounting studs instead of one. The TR6 radiator shroud will bolt on directly and provides pre-drilled holes to mount an oil cooler, but you’ll have to make your own holes in the lower valence.

The chassis and suspension pieces are shared by all those cars, pretty much up to the end of TR6 production. As an example, the steering column switchgear is essentially identical from the TR4A through the first series of TR6, except that the later models have black trim instead of chrome. This transformation was originally made by covering the chrome with black plastic tubing, and is easily reversed! Gearboxes swap, as do differentials (though you may have to retain your original rear cover).

By all means, spend the money required to get a reprint of the factory parts book; unfortunately much of the documentation for the TR4A is produced as an addendum to its TR4 counterpart, but the parts book is dedicated to the TR4A and very clear. Supplement that with the free TR250 and TR6 catalogs from The Roadster Factory and compare part numbers.

Parts are available through a number of U.S. vendors: The Roadster Factory, Victoria British, Moss Motors, etc. TRF’s TR250 catalog is a great thing to get – most of the suspension pieces and many of the accessories are correct, and it’s more detailed than the factory manual in places.

TriumphTune and Racestorations are good sources of competition parts. Ken Gillanders’ “British Frame & Engine” is a Stateside source for many of the best bits from Racestorations as well as a few things that he’s developed on his own – he’s been racing Triumphs since the 50s and is more than happy to talk about them. British Parts NW and FASPEC have uprated suspension bits. The Fat Chance Garage has experience with solid axle TR4As and lots of parts both used and new.